Technical Data

Identification & Functionality

- Chemical Family

- Chemical Name

- Cleaning Ingredients Functions

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- HII Features

- Product Features

- Brine Stability

- High foaming & fast wetting properties*

- Low skin & eye irritation

- Excellent hydrotrope & solubilizing properties

- Excellent stability in strong alkali, acid, and high concentrations of electrolytes

- Compatible with anionic, cationic & nonionic surfactants

- Hard water stability

- Wetting, emulsification, & detergency

- Low toxicity & readily biodegradable

- Exhibits corrosion protection in hard water and strong acids

*Solutions in the isoelectric range (pH ~2.4 - 4.2) may not be clear, but will maintain high foaming properties

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Home Care Applications

- I&I Cleaning Applications

- Application Information

- High foaming food plant cleaners

- High caustic & alkaline cleaners

- High alkaline oven cleaners

- Strong acid cleaners

- All purpose, hard surface cleaners

- Mild personal care cleansers

- Hand dishwashing detergents

- Foaming agent in oil drilling

- Fire fighting foam

- High foam car & truck wash

- Aerosol cleaners

- Compatible with anionic, cationic & nonionic surfactants

Properties

- Physical Form

- Soluble In

- Appearance

- Light yellow liquid

- Soluble in

- Water, Glycols, Alcohols

- Insoluble in

- Oils, Solvents

- Typical Properties

Value Units Test Method / Conditions Density (at 25°C) approx. 1.0 g/mL - Specific Gravity (at 25°C) approx. 1.0 Zwitterion pH Range approx. 2.4 - 4.2 - - - Specifications

Value Units Test Method / Conditions Solid Content 29.0 - 31.0 % - pH Value (as is) 6 - 8 Color max. 3 Gardner

Regulatory & Compliance

Technical Details & Test Data

- Technical Information

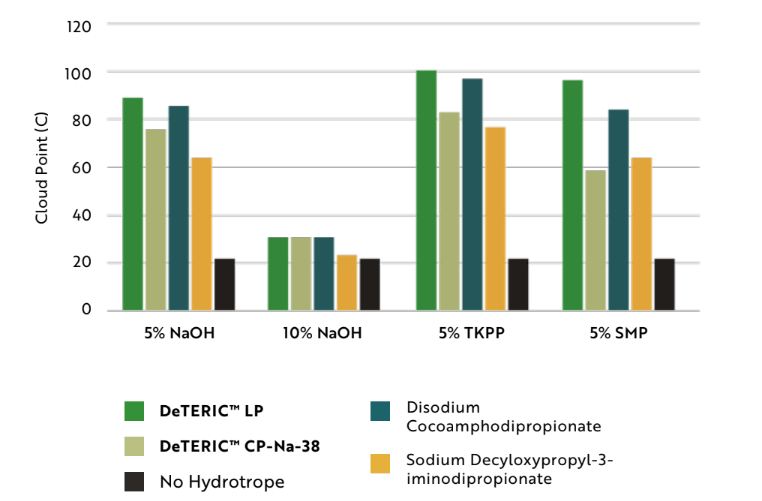

Hydrotrope Properties Data - Deteric™ LP

- DeTERIC™ LP is the superior hydrotrope when compared to other high foaming amphoteric surfactants in several electrolytic systems.

- To determine hydrotrope capabilities, a series of cloud point tests were performed with 3% NPE-9 and 2.5% hydrotrope in the electrolytes listed below.

Chart 1: Cloud Point, °C: 3% NPE-9, 2.5% Hydrotrope (by wt), 94.5% Electrolyte Solution

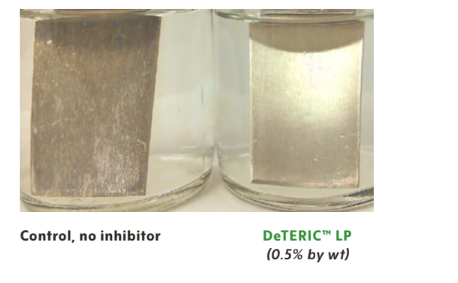

Corrosion Inhibition Properties

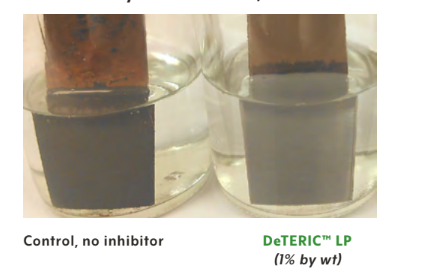

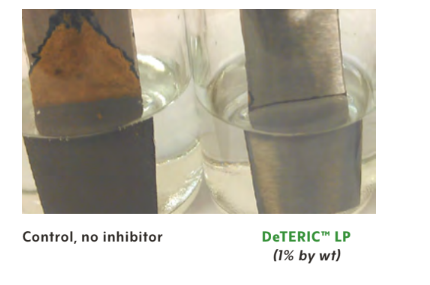

Acid Corrosion Protection

- Metal panels were submerged in the acid solutions and placed in sealed jars at room temperature and observed for signs of corrosion.

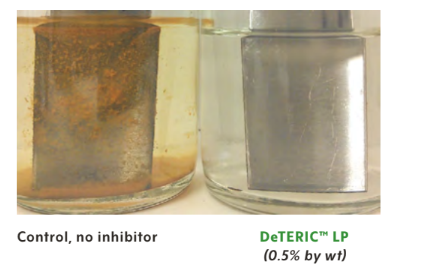

Hard Water Corrosion Protection

- Metal panels were submerged in hard water (100 ppm as CaCO₃ and 71 ppm as chloride) in sealed jars at room temperature and observed for signs of corrosion over time.

5% active Hydrochloric Acid, 72 hours

Cold-Rolled Steel, 72 hours

5% active Sulfuric Acid, 72 hours

Aluminium, 72 hours

Metal Panels: Steel Panels: Q-Panel – Type RS – low carbon, cold-rolled steel, 0.063” thick, 1⁄2 hard Aluminum Panels: Q-Panel – Type AR - Alloy 2024T3 bare, 0.063” thick, 120 hardness

Packaging & Availability

- Regional Availability